Another one? Why?

ZABER 50 years at the forefront, … and unconventional choices !

( click here to see the ZABER website )

Yes, because when Mr. Zaro and Mr. Bertolli, the two partners, more than two years ago took the decision, among the first in Italy to buy an E.cut, and one of the biggest, the skepticism shone through among the collaborators.

But 50 years of iron do not flow at all in the veins, and lead to a capacity ‘of analysis free from conditioning and clichés.

In the face of processes that had always been carried out in a certain way, Ecut represented something completely new on paper.

Keys on large pieces, high and narrow square holes, internal teeth on large bushings, were pieces already ‘previously performed, and of which we knew times and difficulties’. Ecut’s decidedly limited cost also made the decision less “heroic”.

Confirmations arrived in a few months, and as soon as the machine started to be “full”. a decision has been made to buy another one!

The biggest one in production!

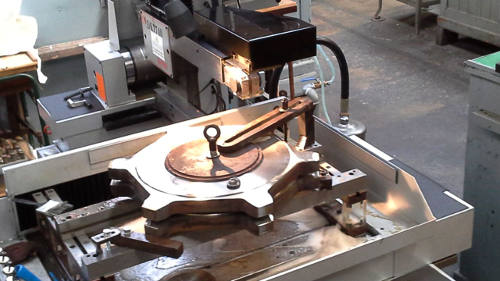

An Ecut 120 with working strokes of 1600×1200 mm, a cutting height of up to 800 mm, and a load capacity of pieces up to 3000 kg.

The economic commitment is a bit greater, but after two years of experience, after comparisons with “as before”, the choice was much less painful.

The possibility of carrying out even small operations, despite the size of the machine, favoured the decision to take the largest one.

Not needing the operator, with a single placement, from a large plate more ‘pieces can be cut, taking advantage of nights, Saturdays, and Sundays.