Based on a dozen modules, more than 70 machine models are manufactured.

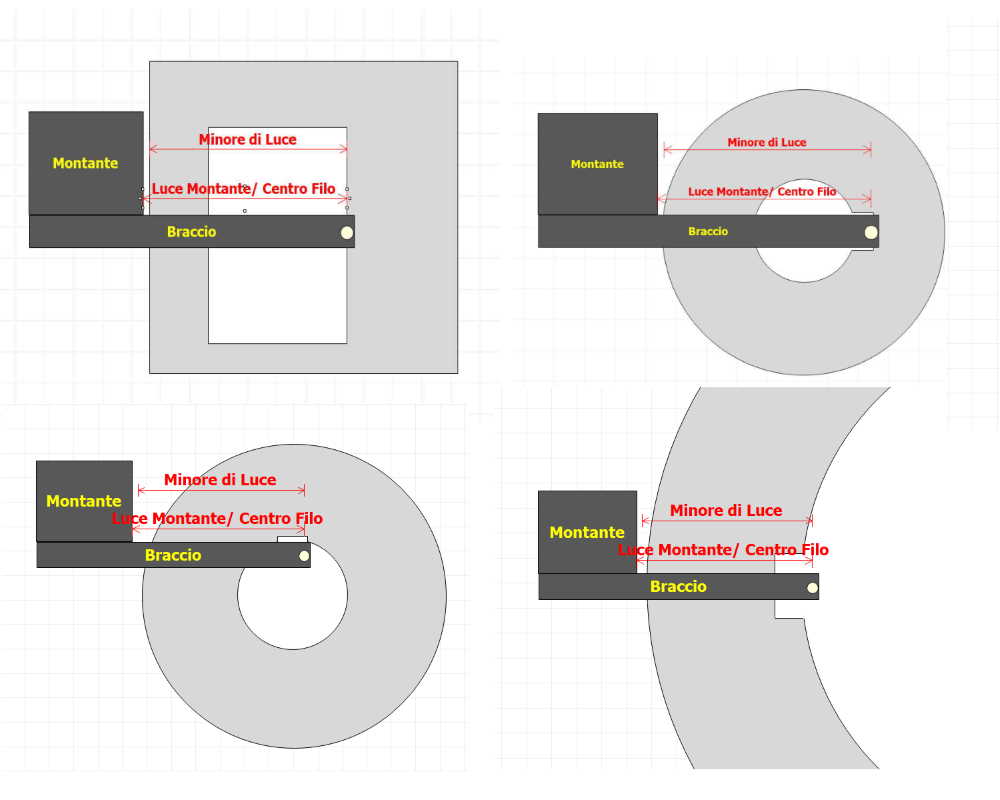

On the same base you can have 3 inclinations, and 3 cutting thicknesses. Two types of generator, and two architectures, (standard arm, and C-Type).

We have some machines for tests and demonstrations, but we prefer not to keep them in stock to be sure to give the customer the right machine for his needs, (and not an old machine).

If it is ready at the factory in 30 days it will be delivered. If it is not ready, it must be assembled, so we deliver it in 60 days.

If you have an urgent need to deliver parts, we will process them for you, and, at the very least, we will supply you with a machine waiting for your machine to arrive!

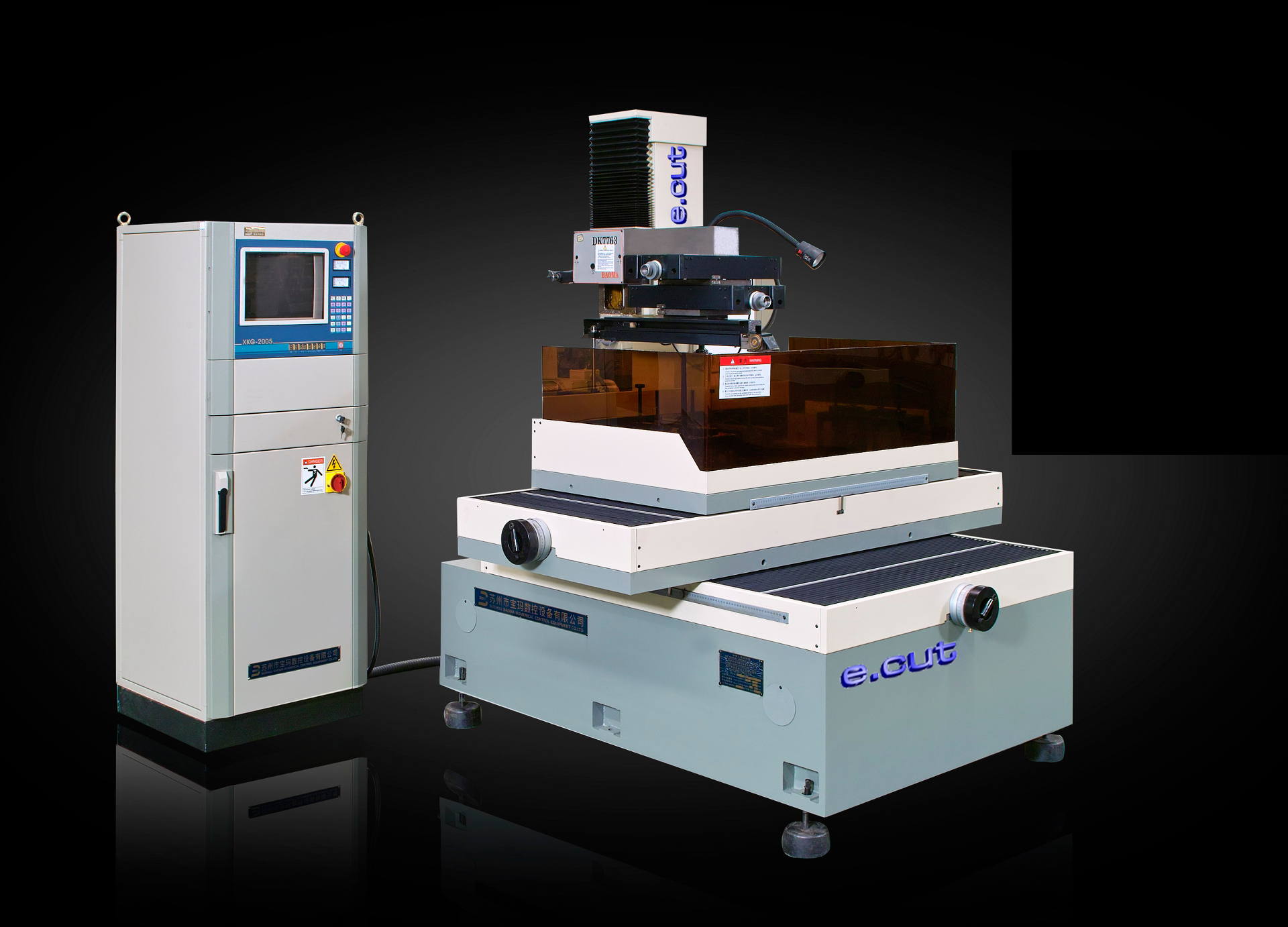

ECUT EU MS

ECUT EU MS is the standard model, sold in thousands of copies worldwide. Like all other models Ecut, built with specifications for the Italian market, has guides in tempered steel and recirculating ball bearings. From 2012, the CNC will be an industrial computer with Windows 7 operating system. A program for the generation of graphics is installed, but it is possible to install Autocad.

The machines of the MS series are the most popular and the most sold. The low cost of purchase and the very low cost of ownership make Ecut convenient already with a use of 50 hours per month (500 hours per year !).

Dimensions

| Code | YX working strokes | Max thickness (mm) | Max. capacity (Kg) | Table size | Light Column/Wire |

|---|---|---|---|---|---|

| ECUT32D | 400 x 320 | 500 (300) | 400 | 415 x 635 | 462 |

| ECUT40D | 500 x 400 | 500 | 500 | 500 x 785 | 537 |

| ECUT50D | 630 x 500 | 500 | 800 | 600 x 900 | 626 |

| ECUT63D | 800 x 630 | 500 (800) | 3000 | 660 x 1100 | 716 |

| ECUT 80D | 1000 x 800 | 500 (800) | 5000 | 800 x 1400 | 901 |

ECUT EU DKT

ECUT DKT is the latest generation model with T-shaped structure, ( like conventional wire erosions ). It can adopt three types of CNC : 3000, 5000, and the new 6000 with easy programming. Standard taper of 12 degrees, special 20 degrees, on 100 mm.

Dimensions

Dimensions

| CODE | YX working strokes | Max thickness (mm) | Max. capacity (Kg) | Table size | Light Column/Wire |

|---|---|---|---|---|---|

| ECUT DKT 32 | 400 x 320 | 300 | 400 | 415 x 635 | 473 |

| ECUT DKT 40 | 500 x x400 | 400 | 500 | 500 x 685 | 562 |

ECUT EU MS C Type

Ecut-Baoma EU MS C type is the new model in which the C-shaped structure is the most striking feature. The biggest innovation is the new BMXP 5000 control, with a higher control capacity and increased power to 8 amps. Together with the servo-assisted electronic tensioner, they increase the removal capacity from 60% to 120%, which can reach 260 square mm per minute.

The machines of the C type series are the obligatory choice for use in production. The high cutting speed doubles production capacity and reduces production costs.

Dimensions

| Code | Working strokes YX | Max thickness (mm) | Working strokes (Kg) | Table dimensions | Light Column/Wire |

|---|---|---|---|---|---|

| ECUT50D-C | 630 x 500 | 500 | 800 | 600 x 900 | 626 |

| ECUT63D-C | 800 x 630 | 500 | 3000 | 660 x 1100 | 716 |

ECUT MS MAXI

ECUT MS MAXI is the series of large size and large capacity machines of the Ecut range configured for the Italian market.

It is not possible to have a fairing for environmental protection, because the large capacity allows to load large pieces, even exceeding the table. The linear guides in tempered steel with recirculating ball bearings guarantee precision and stability. The design with independent slides reduces the height of the worktop.

Dimensions

| Code | YX working strokes | Max thickness (mm) | Max. capacity (Kg) | Table size | Light Column/wire |

|---|---|---|---|---|---|

| ECUT80D | 1000 x 800 | 500 (800) | 5000 | 820 x 1400 | 901 |

| ECUT100 | 1200 x 1000 | 500 (800 / 1000) | 5000 | 1090 x 1600 | |

| ECUT100*150 | 1500 x 1000 | 500 (800 / 1000) | 6000 | 1090 x 1700 | |

| ECUT100*180 | 1800 x 1000 | 500 (800 / 1000) | 6000 | ||

| ECUT100*200 | 2000 x 1000 | 500 (800 / 1000) | 6000 | ||

| ECUT120*200 | 2000 x 1200 | 500 (800 / 1000) | 6000 |

ECUT MS EXTRA

The modular construction of the Ecut machines configured for the Italian market allows the creation of special machines, both in size and characteristics.

The image above shows a machine with strokes of 2600 x 1600 x 1000 mm of cuttable thickness. The arms are mounted on guides with X and Y movements, and the support base of the pieces is fixed (and optional!). The solution allows you to free yourself from the load-bearing capacity of the guides, because the piece is resting on a fixed base.

Another frequent requirement is to have an increased cutting capacity on small or medium machines. By adopting a higher column you can have a cutting height of up to 1000 mm even from the smallest machines.

Special plants can be realized for high productions.

Technical characteristics

| CHARACTERISTICS | STANDARD MODELS CNC> BM3000 | C-TYPE MODELS CNC> BM 5000/6000 |

|---|---|---|

| Removal | up to 150 mm squared per minute | up to 250 mm squared per minute |

| Maximum power | 6 Ampere | 8 Ampere |

| Wire Diameter | da 0,15 a 0,20 Standard 0,18 mm | da 0,15 a 0,20 Standard 0,18 mm |

| Wire material | Molybdenum steel | Molybdenum steel |

| Wire speed | from 180 to 720 meters per minute | from 180 to 720 meters per minute |

| Wire Tensioner | Bidirectional mechanical | Bidirectional mechanical |

| Accuracy (up to mod. 80) | <= 0,012 mm | <= 0,012 mm |

| Accuracy (over mod.80) | <= 0,02 | <= 0,02 |

| Single cut surface finish | < 2,5 Ra | < 2,5 Ra |

| Multi-cut surface finish | < 1,5 Ra | < 1,2 Ra |

| Available with tapering | 0°- 6°/100 mm - 60°/100mm | 12°/100 mm 20°/100 mm |

| Washing liquid | Emulsifiable liquid with natural water | Emulsifiable liquid with natural water |

| Washing liquid tank capacity | 80 litres | 80 litres |

| Power supply | 3 phases - 380 V / 50 HZ | 3 phases - 380 V / 50 HZ |

| Current consumption | Max 3 KVA | Max 3 KVA |

| Axis movement screws | Made of tempered recirculating ball steel | Made of tempered recirculating ball steel |

| Axis movement guides | Made of tempered recirculating ball steel | Made of tempered recirculating ball steel |

| Computer | Industrial PC | Industrial PC |

| CNC operating system | Windows 10 Pro | Windows 10 Pro |

| Graphic program | Standard | Standard |

| Numerical Control | BMXP with parameter database | BMXP with parameter database |

| X- and Y-axis dimensional displays | Standard | Standard |

| Motorized vertical axis | Standard | Standard |

Transport dimensions

WARNING!

Where there are no weights or measures, ask!

The machines are delivered in 3 wooden crates (Machine, Control, Tank).

Inside the crates, a vacuum casing protects the contents. Unpainted metal parts are protected by grease and greaseproof paper.

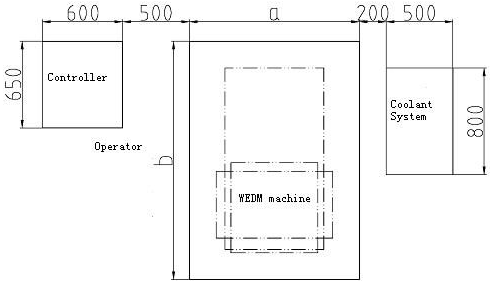

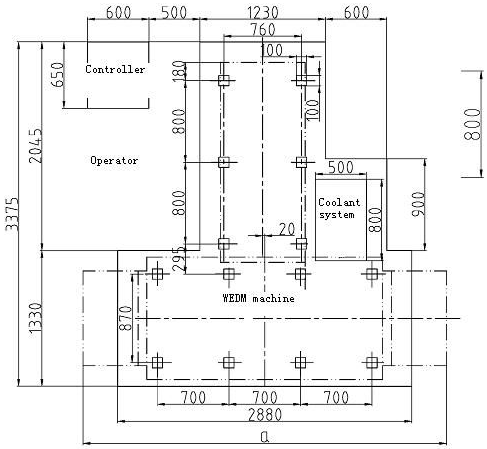

Working dimensions

Refer to the following figures for the arrangement of the work area.

| Type | Width a (mm) | Length b (mm) |

|---|---|---|

| ECUT32 | 940 | 1516 |

| ECUT40 | 1070 | 1676 |

| ECUT50 | 1100 | 1960 |

| ECUT63 | 1400 | 2040 |

| DK7780 | 1630 | 2205 |

| Type | Width a (mm) | Length b (mm) |

|---|---|---|

| ECUT100 | 2660 | 3375 |

| ECUT100C | 3660 | 3375 |

It is advisable to place the machine in a place free of strong vibrations, noise or surrounding magnetic or energy fields and direct it towards a natural light source, otherwise the normal operation of the machine could be altered.

In the event of strong vibrations, use appropriate vibration dampers.

The machine operates in good conditions at a temperature of 20±5 degrees.

Do not place it near another heavy machine and avoid sources of vibration.