Continuous wire erosion

At the end of the 80’s the production of HS high speed wire erosion machines started in China, where the wire wound and rewound on a drum, flows up to 700 mt/min. However, the ingeniousness of the system was not matched by high manufacturing quality. The first attempts to import into Italy in the following nineties were exhausted with the sale of a few machines.

Even today, production in China is divided into “national” and “for export”, as was the case in Italy in the 50s and 60s. The difference in price is considerable, and the fact that some importers have focused on low-cost products has prevented the spread of this technology. After some time of use, at the first breakdowns, often the manufacturer disappears, and the ‘Italian user found himself with a machine paid little, but unusable.

Unfortunately, even today someone still chooses this path, after a while it stops, leaving discontent, resentment and distrust in this technology.

At the end of the first decade of 2000, Genesi, with its thirty years of experience in the sector, resumed and examined in depth the reasons for these failures, and proposed technical and commercial changes to make the product “industrial” and “marketable” in Italy. After several attempts, the meeting with BAOMA marked the turning point, allowing Genesi to present a product with “Italian” characteristics.

An “industrial” product, made by a leading company in China, one of the first to obtain ISO 9000 certification.

Baoma Group

Baoma is one of China’s leading private and exporting machine tool manufacturers. Located in Suzhou, near Shanghai, in a mechanical district with high industrial development.

Since its inception, it has been characterized by extraordinary and rapid development due to a global vision that guarantees continuous growth and constant expansion in world markets.

Under the leadership of its founder and president Mr. Shao Jianjun, the company has achieved both ISO9001:2000 and ISO14001:1996 certification. Few other companies in the industry have both.

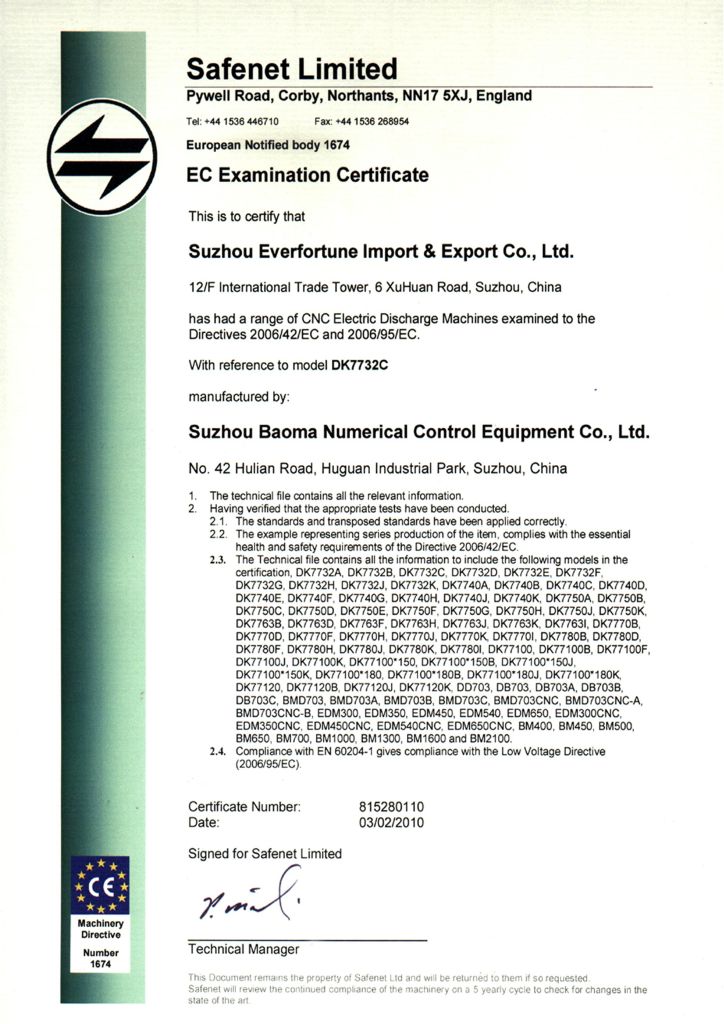

All products are recognized and certified with the CE mark.

Baoma develops, manufactures and sells CNC & EDM machines worldwide under the slogan “Looking to the future, building now”, focused on organizing and “raising” a team of young people with high capacity for independent and autonomous development.

Five patents and two grand prizes for “product reliability” and “quality of after-sales service” are the result.

Suzhou Baoma CNC Wire Cut EDM machine is at the top of the quality with its strong tilting machines, large size, high efficiency and accuracy of construction.

The development of the BMW-2008 High Speed Wire Cut EDM generator puts Baoma machines in competition with conventional WEDM machines for the high degrees of finish and precision of work.

In the local market is the “second generation” machine, of the companies that after years of use of these machines want a product of superior quality.

Baoma collaborates with leading universities and design companies worldwide in order to constantly research and develop new technological solutions.

Baoma machines are exported to Poland, Germany, America, Italy, Russia, and other countries, and used in the fields of moulds, mass production, aeronautics and astronautics, the weapons industry, and the Gas & Oil sector for the processing of difficult materials.

Baoma pays a lot of attention to the environment and invests in R&D to have “green” products. To tackle the problem of pollution Baoma has researched more than 800 different methods to develop the series of water-based, anti-pollutant BM liquids.

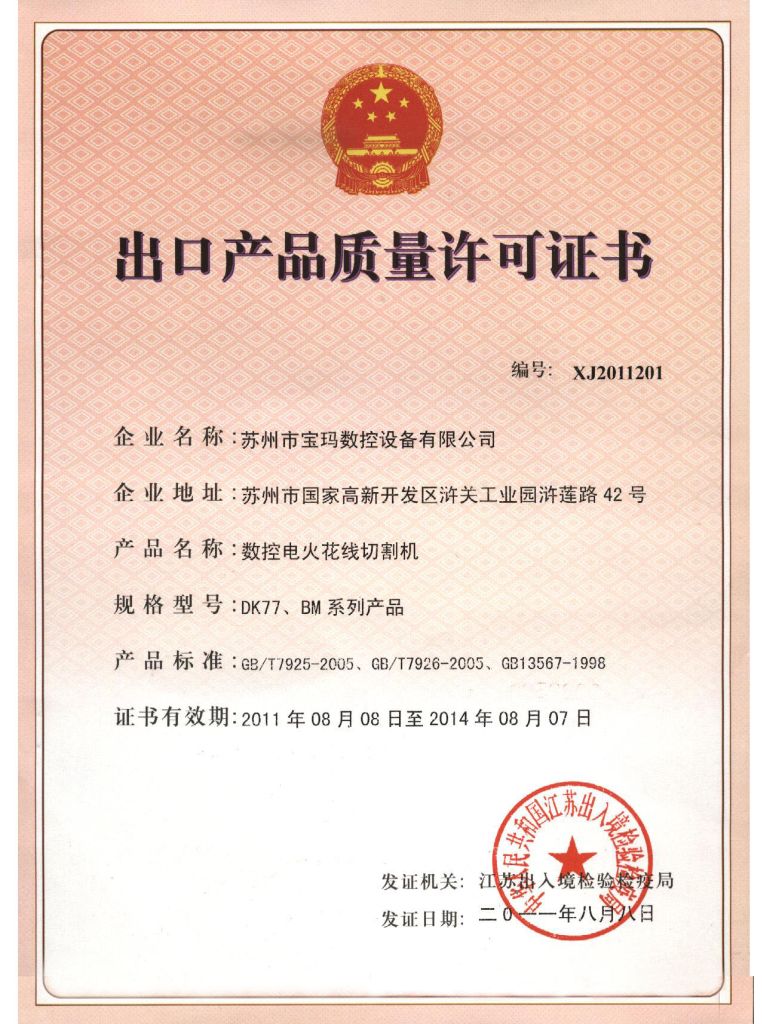

BM products are certified both internally and internationally by SGS-CSTC CERTIFICATION, and in Italy Genesi has obtained the Safety Certificate. This revolution in working fluids is covered by 12 invention patents and has won more than 30 awards.

The collaboration with Genesi allows to supply the Italian market with machines with characteristics of standardization of mechanical and electronic components that make the product “industrial”, facilitate the assistance, and guarantee the investment over time.

ONLY the machines with E.cut serial number are guaranteed to replace damaged parts even after years.

ONLY with these serial numbers it is possible to tele-assist even directly from the factory.

Genesi has a warehouse of original Baoma spare parts and consumables produced or selected directly by Baoma.

A machine for each model (standard or C type) is always available for demonstrations, tests and tests on particular materials.

The Genesi service assists directly, and through the technicians of the factory, the customer for problems of processing of particular materials, clamping or positioning for mass production.

Special machines are possible.