Production data collection and progress control.

The experience of one of the companies that is part of GenesiGroup in the development of systems for collecting production data,has led since well before the law 2017 on hyper and then super depreciation was enacted, to the ‘insertion on Ecut machines of a system for recording the work done, and in progress.

It is a simplified version of a much broader application, but it was made with the goal of giving the user a simple and direct way to record the work done.

By hovering the mouse over the images, it is possible to zoom in with the mouse wheel

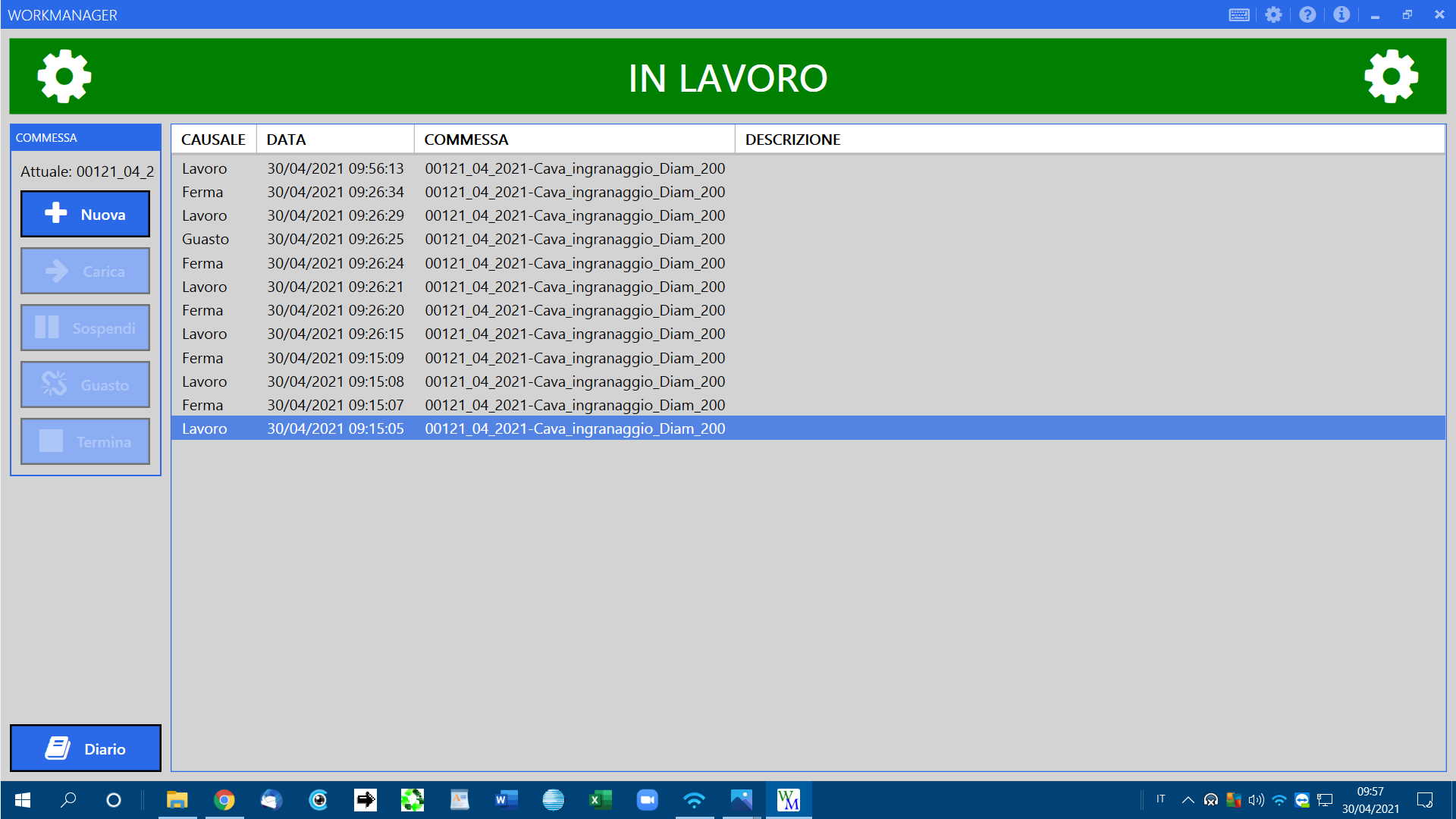

WorkManager, the data collection program, can be active at all times, even while the machine is working, or while the operator is making a new work program.

When it is opened, the current status of the machine is presented, what machining is in progress, and the list of events since the beginning of the current job.

If the machine is working, there will be no commands for activating a new job, nor will there be any failure causes.

It will only be possible to generate new jobs, and to see the logs of jobs already executed.

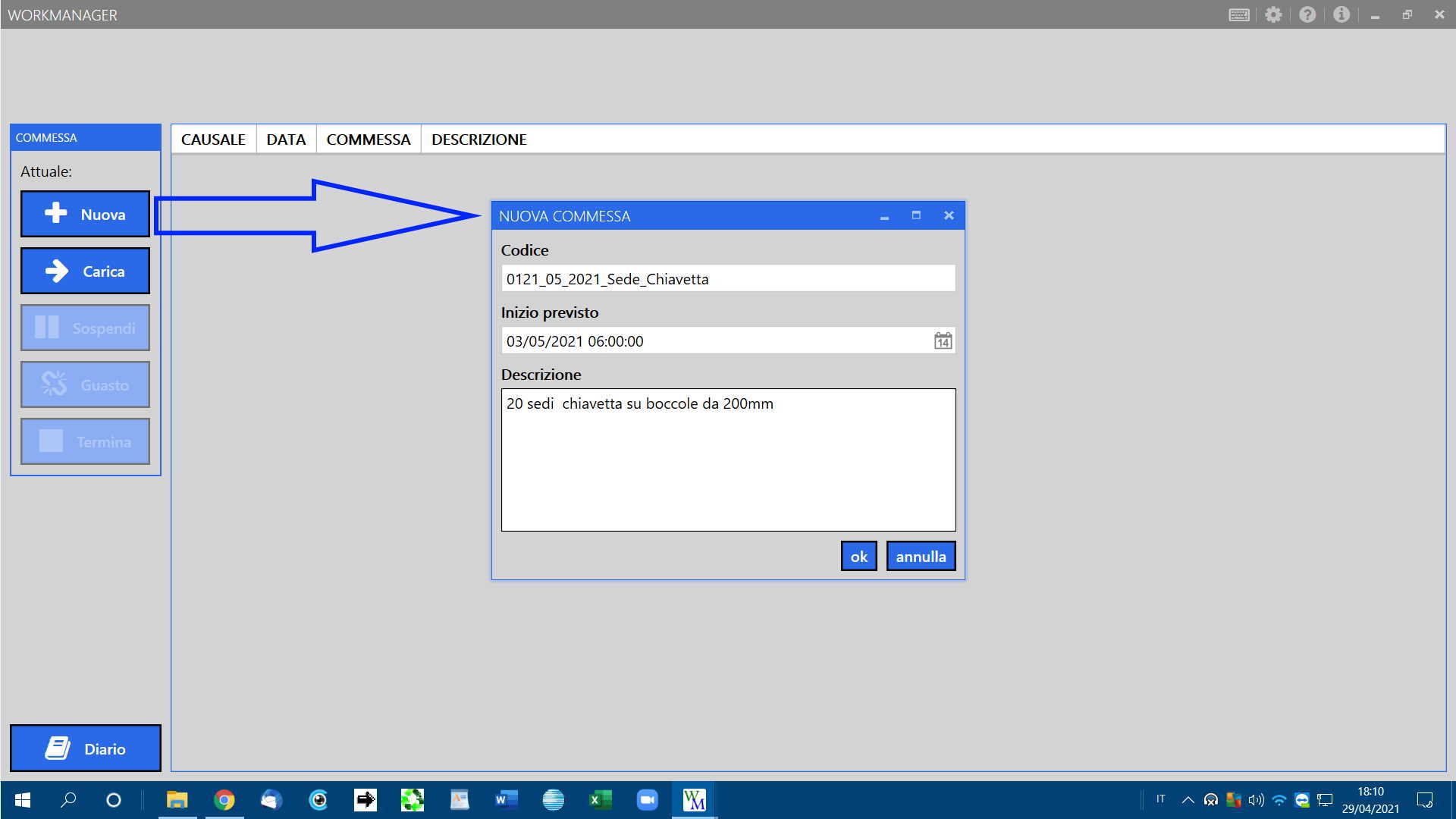

At any time, whether the machine is working or stopped, the operator can add entries to the ‘list of jobs to be performed.

Since Ecut is on the network, and the remote control program is normally installed, this activity can also be performed remotely, by the person responsible for scheduling workloads.

The list can be generated and managed elsewhere, and sent periodically to the machine. In this case, the operator will not have to perform any activity on the list, but can still enter “last minute” processing

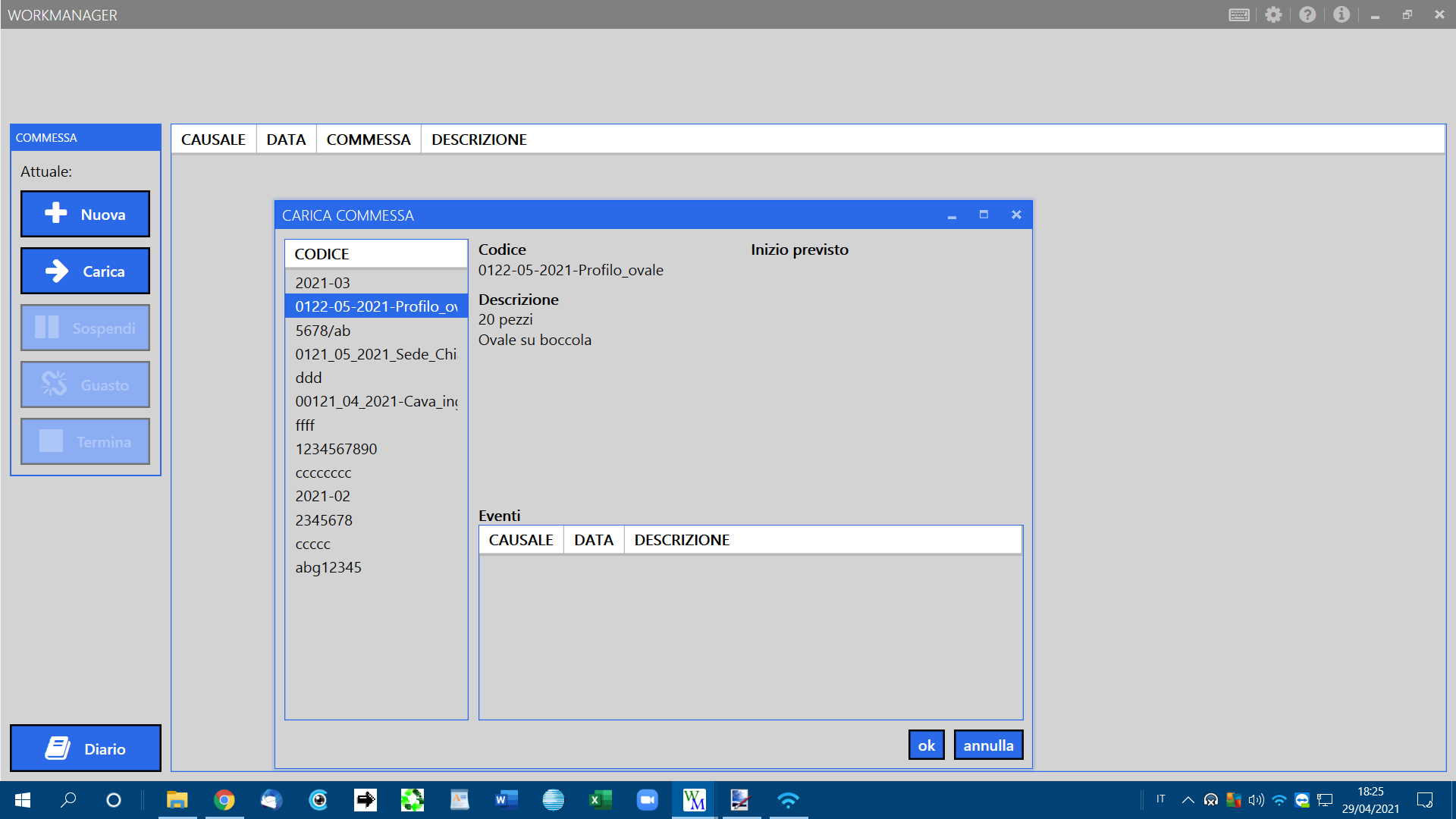

With the machine stopped, and the job finished or suspended, it is possible to load a new job.

Clicking on the load button opens the list of jobs to be executed, from which the operator can select the desired one.

Suspended jobs will also appear in the ‘list, and selecting them will allow processing to continue, and related events will go into a single journal.

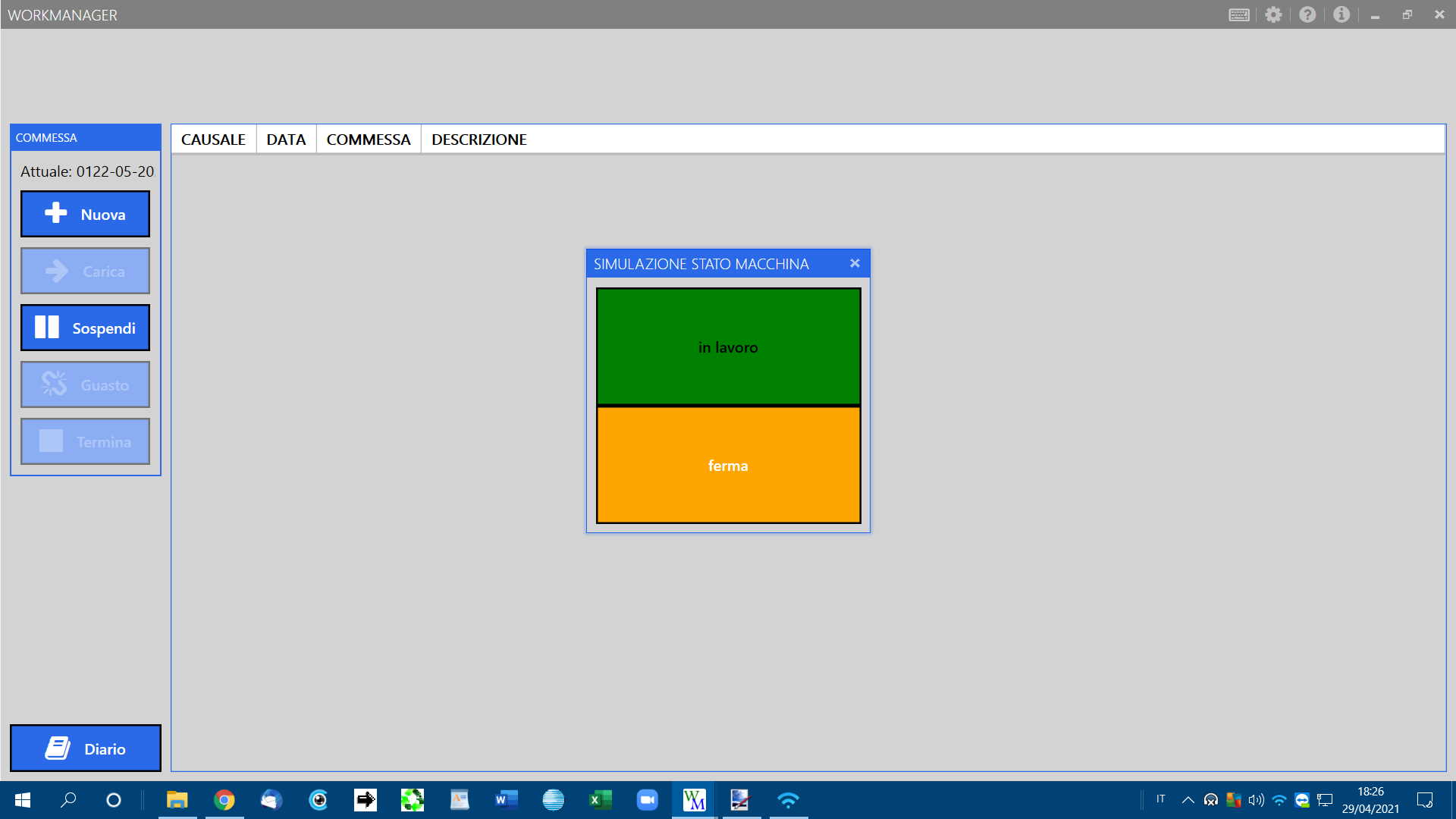

The status of the machine can be entered either manually or automatically, (option ).

Clicking on the relevant buttons will write the relevant status message in the journal with its date,hour , minute and second .

When the machine is working only the stop key will be enabled. Only new jobs will be able to be entered in the ‘list, and job diaries displayed.

At any instant the ‘operator will be able to view the diary of the jobs.

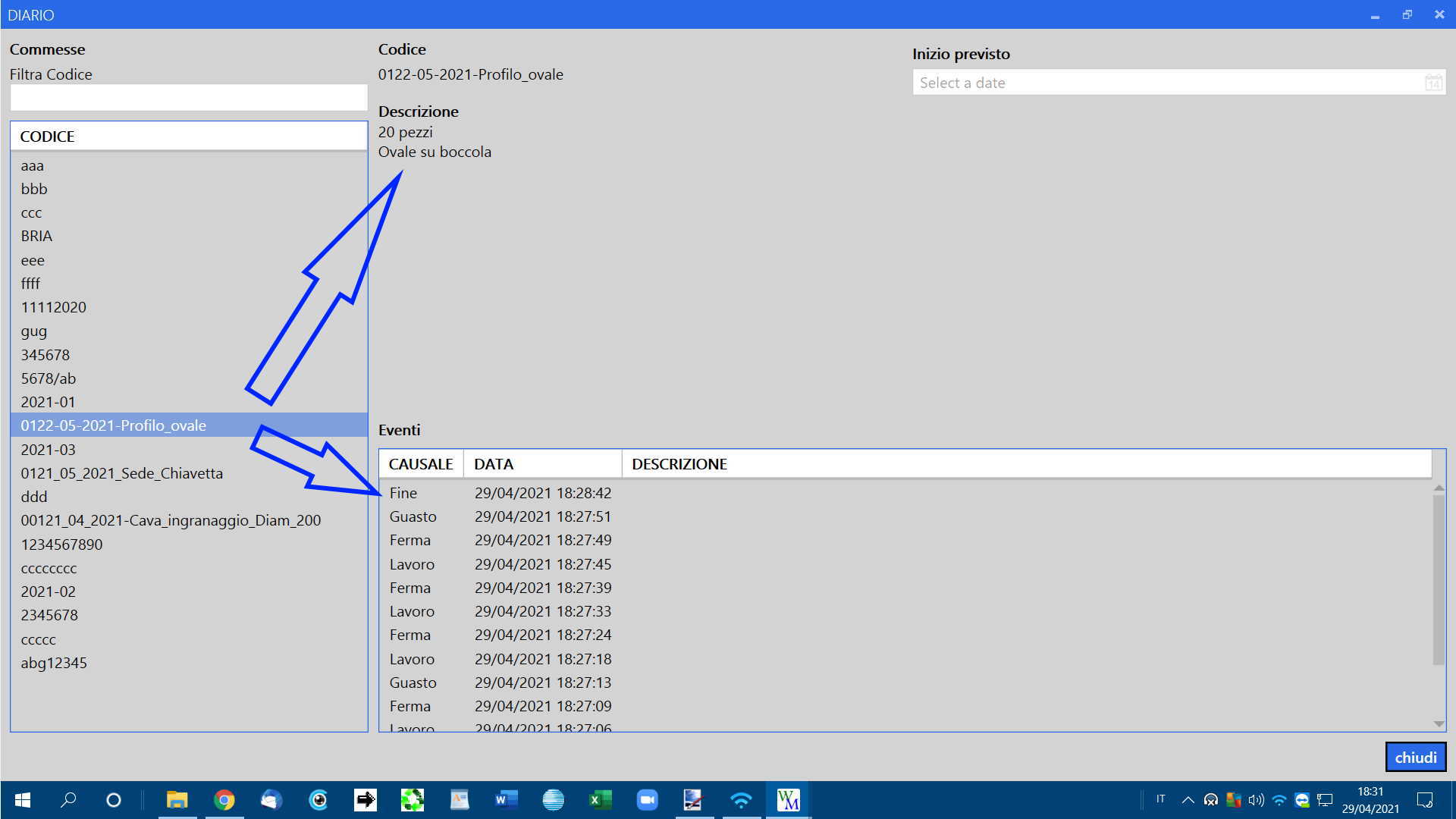

When a job is selected, the related data will be displayed, and below it the diary of events with related causes, date and time,minute,second.

The visualization of the diaries is possible at any time, even when the job is in progress, and since the machine is networked, it can also be done remotely.

The ‘list of orders to be executed can be imported into the program from a text file prepared elsewhere.

The file will need to be updated containing new orders to be executed and suspended orders, with the new expected execution date indicated.

The ‘list should contain rows with the following fields:

Job code ;Scheduled start date and time ; Description/notes

Collected data are stored in a machine journal.

They can be exported and be available for ‘management system analysis.

Rows with events appear in the diary in the following format:

Cause of ‘event (start,end,work,stop,fault) ; Date/time/minute/second of event ;Notes