Purpose Compliance

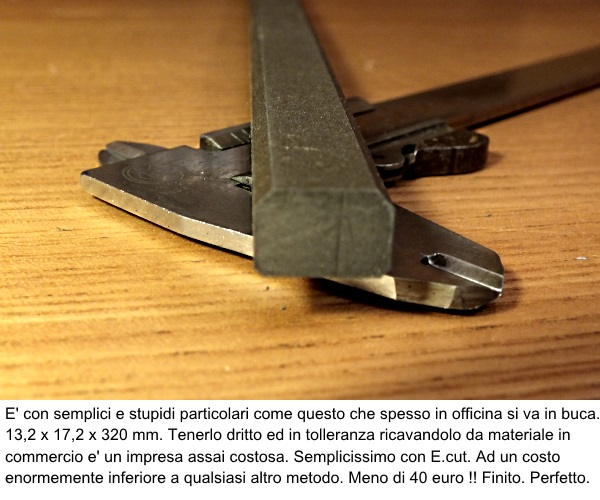

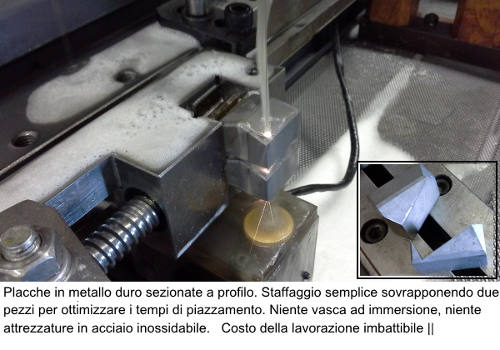

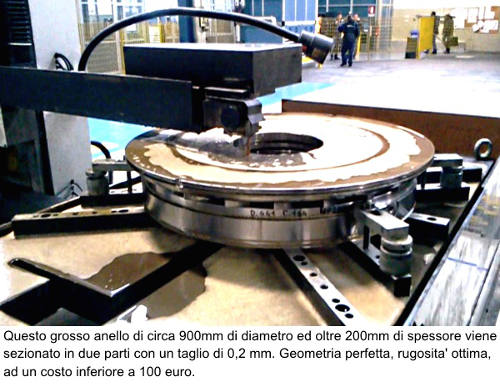

To make machining more economical, even if there are not large quantities, and often for a few or just one piece to be performed.

Wire erosion is in many cases the most economical solution. But for those few times it is not conceivable to buy one. If used, the risks of malfunction, the high cost of ownership, and the complexity of the operation advise against buying.

It remains to do so to a third party. But even here, high costs, out-of-control delivery times…

Ecut is becoming the solution.

In many companies have understood this… But they don’t tell anyone.