About genadmin

This author has not yet filled in any details.

So far genadmin has created 181 blog entries.

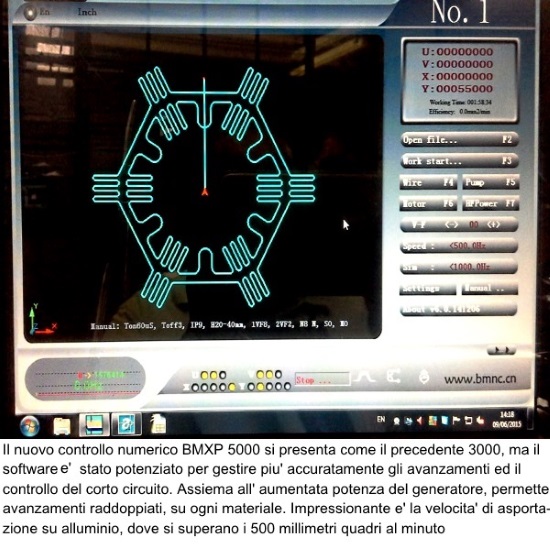

Ecut is proving to be the ideal partner in rapid prototyping thanks to some features that make it significantly superior to a normal wire erosion.

1) High cutting thickness, 500 mm, even for the smallest (and cheapest) models.

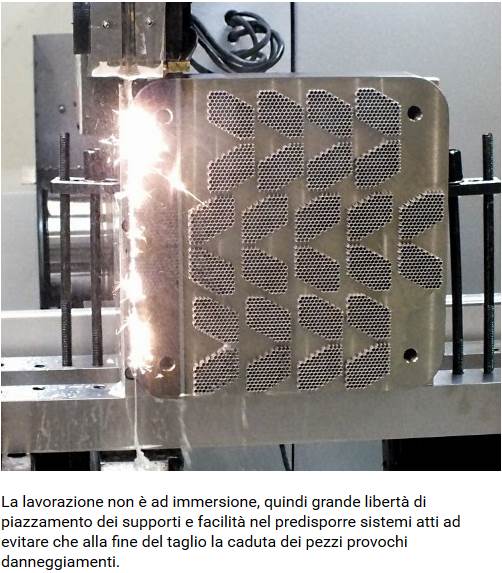

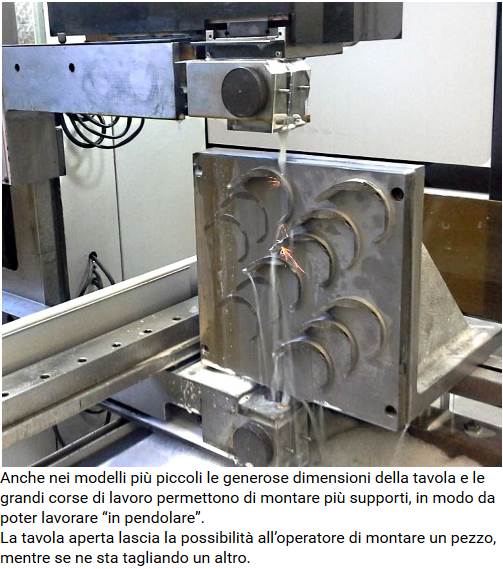

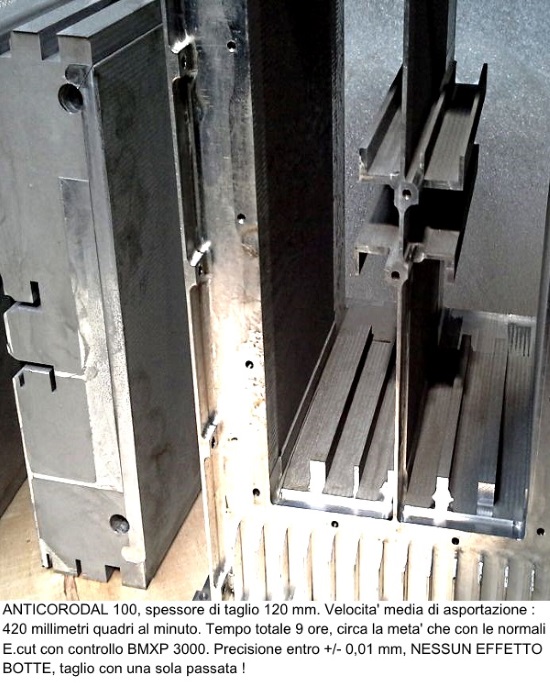

2) Regular cut even in the presence of discontinuity of the section. The images below are a typical example. Ecut’s cooling and washing system is drop-down and is effective even if the cut is interrupted

3) Cutting not affected by the presence of dust of the material inside the cavities.

4) Cost of operation 10 to 20 times less than that of normal wire erosion

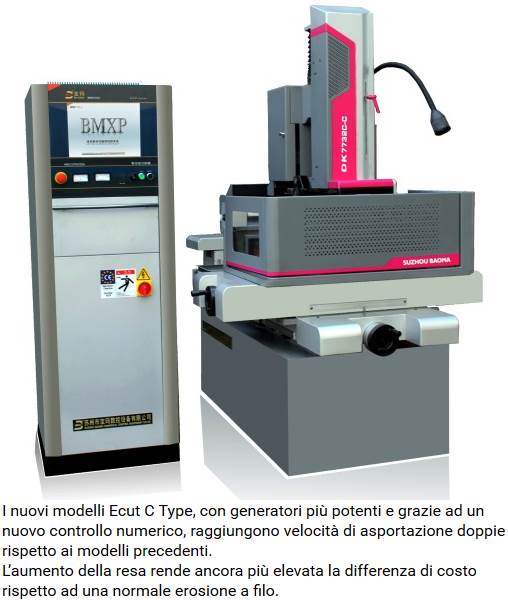

Ecut Baoma is also at the forefront of aluminium processing with the new C Type models.

The following two pieces have an incredibly low cost of execution.

Considering the pure cost of operation, therefore consumables (wire, water additive, annual maintenance and energy cost) the processing of the heatsink in AVIONAL costs less than 4 euros, while the drawer in ANTICORODAL 100, about 18 euros!

Considering not only the cost of operation, but also the cost of depreciation, we have for the heatsink fifteen euros, and for the drawer 65 euros.

That’s why large Italian companies that are attentive to new technologies are increasingly buying an Ecut.