Ecut in the living room

A love at first sight. It often happens with Ecut.

The young owner of this large company immediately understood the potential of Ecut. Having tried a demanding process at the Genesis laboratory, he ordered a machine. He assessed the punctuality of delivery times, the efficiency of installation and commissioning, and more importantly, the speed with which, under the guidance of Genesi’s technicians, his operators learned to use the machine and start producing. In the space of three weeks, in view of the reduction in costs on machining operations previously carried out with removal machines, he ordered the second machine.

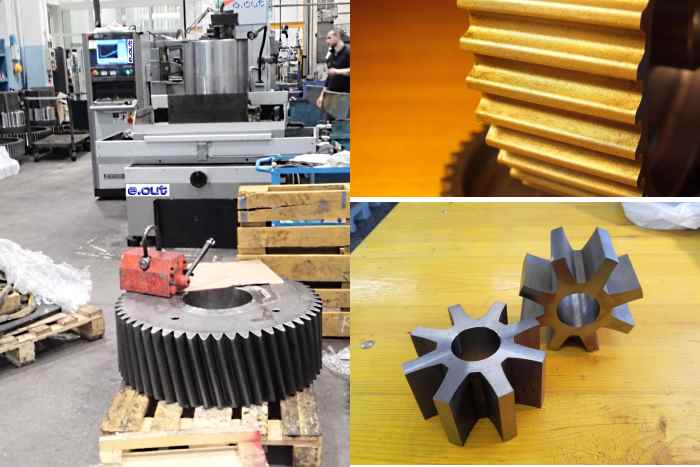

These parts could be machined by conventional machining.

The material, however, is a particularly difficult stainless steel. The very tight tolerances required, and the required unachievable milling finish, required grinding operations.

The part obtained with Ecut has tolerances well within the required values, the final roughness has avoided grinding.

No cost for tools, inserts, or special clamping equipment. In two placements the part is finished.

The cost is well below how milling could be achieved, and much lower than using conventional wire erosion.

The end customer was very satisfied. He paid a little less than usual, and the contractor who did the work earned a lot more than usual.

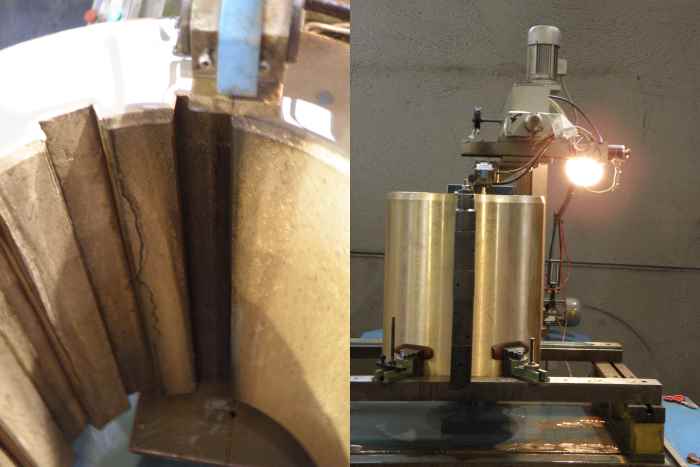

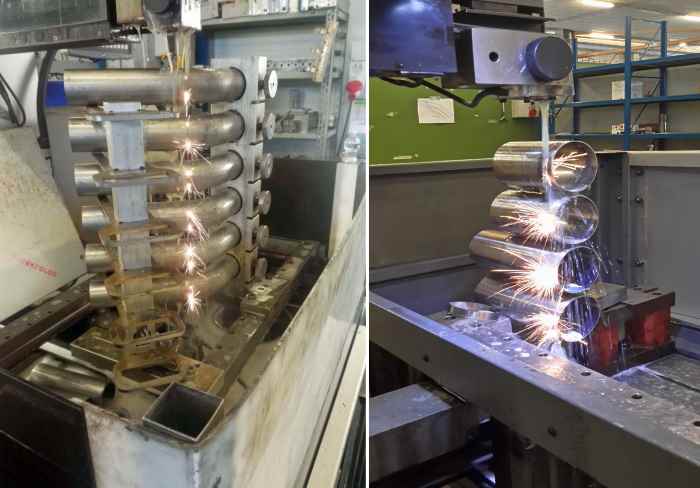

Tube processing is one of the areas where Ecut excels.

Not straight cuts, thin thicknesses, “cursed” materials, see wire erosion as the ideal solution.

But conventional wire erosion occurs in an immersion tank, which is often smaller than the length of the tubes. Moreover, washing “under pressure” is not very effective on a tube, and prohibitive on a series of tubes.

Ecut has no immersion tank, the cooling of the cut is obtained “by gravity”, and already ‘from the smallest machines’ has a cutting thickness of 500 mm.

The lack of the tank and the wide working strokes allow to mount more clamps, and to work “in pendulum”, obtaining an optimal productivity.

The completely burr-free cutting, especially in very thin thicknesses, makes Ecut a solution technologically, and economically irreplaceable.

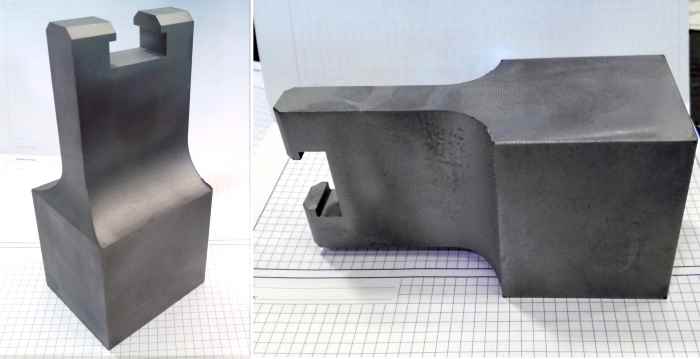

Mr Alderighi’s company, Aldepack, is not a big company.

It is an excellence in the field of packaging machines, and exports all over the world.

The workshop is small in size (they have everything done outside). They take care of the design, and assembly. They have those few necessary machine tools, and every now and then they happened to do wire erosion workings, but it was always a pain. Costs “from molds”, delivery times never known, and often the work done not exactly as they wanted.

It’s unthinkable to buy one. For the high cost and never amortizable, and for the complexity of managing a wire erosion.

They asked Genesi to do some work, they saw the machine running, and Mr Alderighi, a mechanic for generations, “fell in love” with it. The cost of purchase, the cost of operation, the simplicity of operation, have been the reason for the “fall in love”.

In the end, he bought it. They have changed the design of different pieces, simpler, more functional, more precise, (obtained after the heat treatments).

Spiritually, they sanctified her by putting a crown of light on it!