High precision,.. Low cost !

The accuracy guaranteed by E.cut is +/- 0.015 mm. A precision into which most of the machining operations fall.

Almost always a precision of this type is the result of roughing and finishing operations. Even in the case of conventional wire erosion, when the thickness of the wire exceeds 100 mm, the “barrel” effect comes into play, so that in the central area the cut is sometimes a few tenths wider. A revision is therefore necessary.

E.cut, thanks to its wire reuse technology, allows such a high sliding speed that the barrel effect disappears, so that with a single pass the cut is perfectly tailored. Dimensional and geometric.

The thickness of the cut, (from 300 mm. of the smallest to 800 mm. of the largest), does not affect the precision at all,

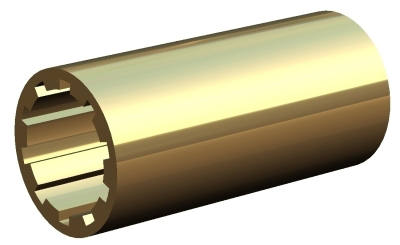

In the figure to the side, the 330 mm high bushing requires a 12 mm wide by 8 mm deep groove, and the result is within a hundredth.

No

tool, no tools for gripping, very simple program.

Beyond the pure cost, which is not real with E,cut, the difficulty that a similar process presents, often discourages the designer, and when it is not possible to do otherwise we go with wire erosion. Machines that work so thick are not, however, in the possession of many, and the cost becomes very high. Often prohibitive.

The incredible precision/cost ratio of E.cut opens up new possibilities already at the level of design of the pieces.