Small productions at low costs

These small teeth, made of particularly hard material, should be obtained from an ad hoc profile, from which the pieces are cut.

The problem is that there are no quantities!

The cost of the drawing line, and a minimum of production of drawn parts would be prohibitive to produce a few hundred of these pieces.

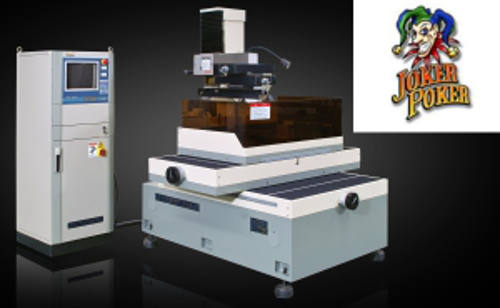

The precision required makes the cost of obtaining them from machining very high. Laser and water cutting do not guarantee tolerances and roughness, so the possible solution is wire erosion.

Any conventional wire erosion has a cost of operation, (wire, distilled water, ion exchange resins, filters, and … maintenance) ranging from 10 to 15 euros / hour.

The cost of each piece is therefore about one euro. 500 pieces cost 500 euro.

cut has an operating cost that does not exceed 40 cents per hour, so, in abundance, each piece costs less than 5 cents. 500 pieces cost 25 euros!

The difference in cost is not, however, the only advantage.

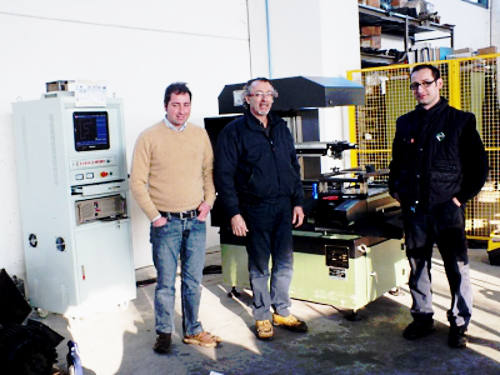

With Ecut, the “open” machining, i.e. not in a immersed tank like conventional wire erosion, makes the fastening equipment extremely simple, inexpensive and easy to place. You can do this during the day, and leave the machine “in production” at night!

Another important aspect is that the cost does NOT depend on the quantity to be carried out. Producing 10 or 5000 teeth has a cost per tooth that is always the same.

The economic quantity of production is 1! So do not put under at least 500 (or 5000), otherwise they cost too much.

If you need 224 pieces, produce 224, not 5000!

Let’s beat the Orientals with their weapons!