Springs… and spring material

The difficulties in machining spring steel by removal are well known, and always faced with reluctance.

When it is absolutely necessary, usually when samples or small series of pieces are required, the final costs are high and the results unsatisfactory, both because of the difficulty of maintaining precision, and because the machining operations (drilling, milling, turning, ..) “stress” the material to such an extent as to compromise the final functionality.

The solution often adopted is cutting with conventional wire EDM. Often it is the only solution but the cost limits its adoption considerably.

Ecut technology opens up completely new possibilities.

The extremely low hourly operating cost (more than ten times lower than that of conventional wire EDM) is the most important factor.

If in fact cutting a pack of 50 discs of 50mm diameter with conventional wire erosion costs (*) around 60 euros, with Ecut does not exceed 6 euros!

Two other factors are important.

The first is that Ecut technology does not cause surface and micro cracks (absolutely forbidden in various sectors, such as aeronautics, X-rays, etc.) which are particularly harmful in the case of springs.

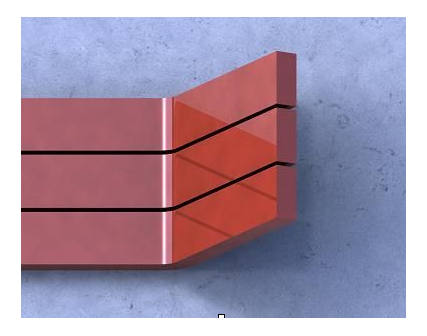

The second is that even the smallest model of Ecut can cut thicknesses up to 300 mm. Clearly, the springs are only a few millimetres thick, but such a large thickness of cut allows you to work “columns” of hundreds of pieces at a stroke, further reducing the cost, and also making interesting the execution of a few thousand pieces without having to deal with the construction of moulds.

(*) hourly cost of operation = cost of depreciation + tool cost + cost of wear and tear parts and consumption + cost of maintenance