Thin tubes, not always easy

How much does a smear cost?

Often in production the nose is slammed with problems of apparent simplicity but underestimated in terms of cost.

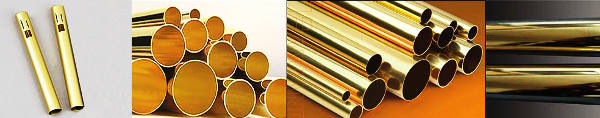

The processing of thin tubes, whatever the material, but especially when expensive and valuable, makes it necessary to take precautions and care that increase costs.

Tubes of a few tenths of a thickness cannot be tightened without criteria, under penalty of deformation. Therefore, shaped pliers and special, special tools, and as such expensive, must be studied.

Cutting with conventional methods, but also with lasers, water, etc., always leaves burrs or micro burrs whose accurate elimination is almost always considerably more expensive than the cut itself.

If the cut is not straight, but has a profile, the use of shearing dies is necessary.

In the presence of large lots, everything is justified, but when there are no large quantities, the matter becomes complicated.

Electroresion has been used for decades to cut the tubes of hypodermic needles, but there, the high numbers have justified the use of special wire EDM machines.

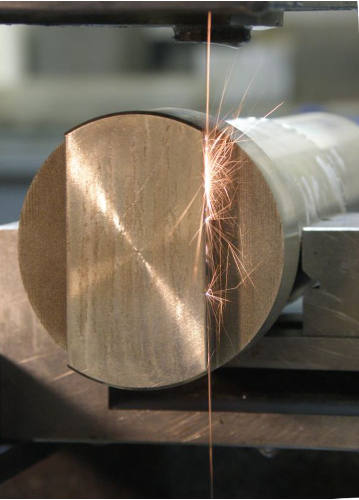

Wire erosion cutting would be ideal. No need to tighten the workpiece, just keep it in place. No burrs, clean and precise cutting, and, given the very thin thicknesses, even short cutting times.

The problem is the high hourly cost of operation, and the fact that these machines are not mixed up with the production men. ( They are not all mould makers ! ).

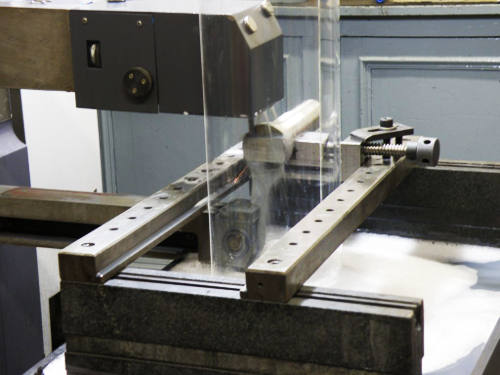

E.cut represents a revolution.

The hourly cost of operation from 10 to 20 times lower than that of conventional wire erosion, the extreme simplicity of management, and even more ‘the ease’ of use within the reach of any worker, make it unbeatable adoption in these cases.

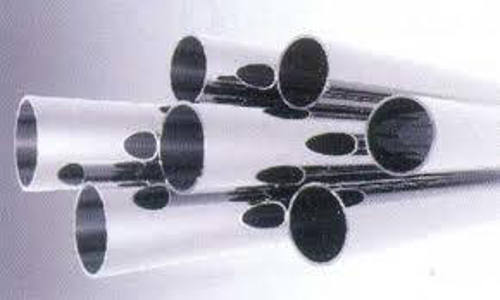

Incredible cut of 4 superimposed stainless steel tubes. Cutting practically impossible with conventional wire erosion, except with very low cutting speeds.