Scrap?

In the shop, an old wire erosion is a very bad deal.

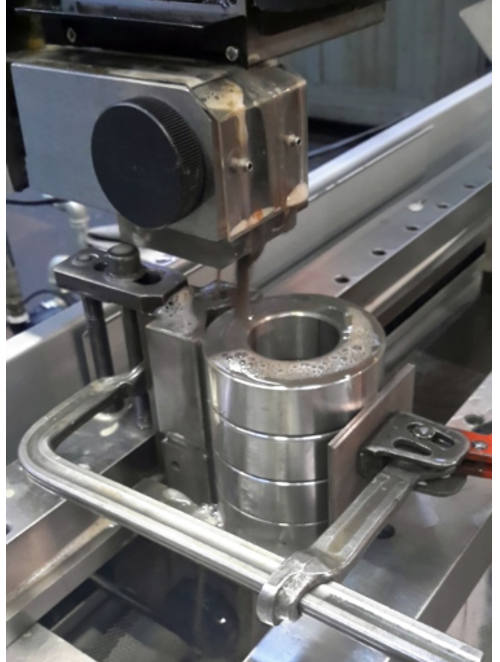

The advent and spread of the new Ecut wire cutting technology makes the use of old wire erosions obsolete and uneconomical.

In fact, the hourly cost of operating an old wire erosion is around 10 euros/hour, while an Ecut has an hourly cost of 0.5 euros/hour.

By hourly cost of operation is meant:

For old wire edm: Wire cost, distilled water, resins, filters, electricity, maintenance.

For Ecut : Wire cost, emulsion with normal water, filters, current, annual maintenance.

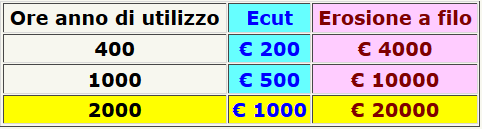

Considering 3 types of use:

1) Sporadic use 400 hours per year

2) Limited use 1000 hours per year

3) normal use 2000 hours per year

the related costs are :

Considering only the operating cost

Considering Ecut with operating cost + depreciation cost, and old wire erosion only operating cost:

It is clear that it would be much more convenient to “scrap” the old wire erosion and use a modern Ecut.

In fact, examining the values of the yellow line of the first table we can see that over 2000 hours the use of Ecut involves a saving of 19,000 euros / year. An Ecut would pay itself in a couple of years, only with the money saved!

If you go to the page HIRE, you can see how already ‘with 700 euros per month you could have an Ecut.

By renting an Ecut you will be more competitive, and you will save a lot of money!