2, 3, 4,.. Ecut grow like mushrooms

Sure, they grow like mushrooms…

Those who start using an Ecut quickly realize how many pieces can be made much more conveniently by changing the method of processing.

Obviously the technology of wire erosion is not a novelty, but the high hourly cost, the relative slowness if compared to conventional machining and the consequent high cost of realization of any machining, have relegated its use to the sector of moulds, and a few other sectors.

The low operating cost, and therefore the dramatic reduction in machining costs, represents a revolution in the mechanical machining sector.

One thing, however, is to say it, and another thing is to do it.

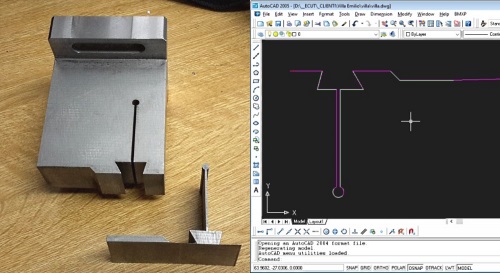

The following images are of customers who have touched with their hands the first machine.

The following image is of a customer who after a while was unable to do what he had bought the first machine for. Every now and then someone from the technical department would go to the workshop to smoke a cigarette… and then they would change the way they made some pieces. After a while they bought the second one.

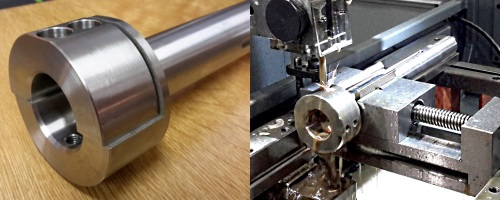

They make rapid prototypes, they are among the leaders in Italy, and a machine was no longer enough.

For a question of size, … but also of growth of work.

These are a branch of the world’s largest mechanical engineering company. After only 4 months of use of the first machine they ordered the second one.

A few months after buying a very expensive Japanese car, they discovered Ecut. The smallest and cheapest Ecut does almost the same production as the Japanese. Tried it, and after a few months it took another one. Doubled the production with two machines and less than a third of the cost of the Japanese.

After two weeks from having installed the first one, the big one at the bottom, and having started to do some work, they decided to eliminate an expensive work, carried out on a very expensive machining center, and to buy the second one, the…

Here we had to widen the holes of 800 rollers. In the space of 18 months!

Once all the cutting parameters had been checked and the maximum removal speed had been obtained, another 3 machines were purchased. The total cost was however lower than the cost of a single Swiss machine. But the production has almost quadrupled!

Gas&Oil. After testing and trials with us, they wanted to buy four machines immediately. We suggested that only two of them should be medium in size. After one year, they ordered two more. One bigger, and one of the new C-Type model, faster.