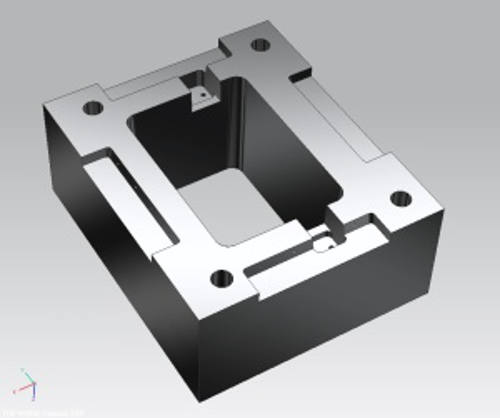

Digging out die-holder plates, making deep grooves.

Digging a plate to get the seat of dowels is a basic processing in the executions of moulds.

Of any kind they are, for sheet metal, plastic, or die-casting, the execution of extensive quarries, especially when the depth ‘begins to become high, engages large machines and expensive tools.

Often they are not sophisticated and expensive machines, but for this reason they need the presence of the operator. And the operators themselves are almost always expensive.

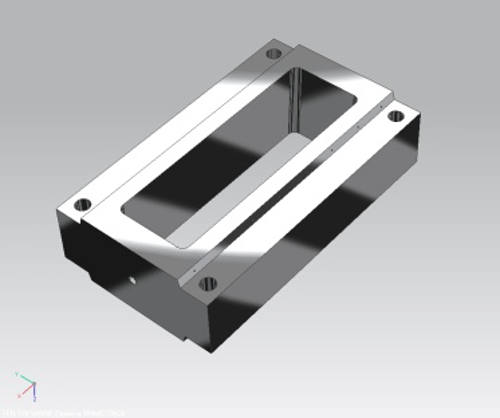

The decomposition into two plates, one at the bottom and one for the quarry, allows the use of wire erosion, but only by having one, there, ‘firm and unused.

In many companies, where there is wire EDM, sometimes it is done, without paying too much attention to the costs, and with many limitations.

The dimensions of the plate are not always in the machine tank.

If the thickness to be cut is more than 150 mm, the machines that can process it begin to decrease, and those that can do so cost more.

The hourly cost of operation, (brass wire, distilled water, resins, filter cartridges, etc.), is justified for work with high demands for precision and finish, but for the execution of a simple quarry, they are often prohibitive.

E.cut does not work by immersion, so the plates can also “come out” of the pallet.

The maximum thickness that can be cut starts from 300 mm for the smallest machines, up to 500 / 600 mm for the largest ones.

The wire is not “disposable”, and flows at a speed of 100 times higher than a normal wire erosion. No demineralized water, no ion exchange resins, no filter cartridges are needed.

The hourly management costs are 10 times lower, not exceeding 0,40 €/hour.

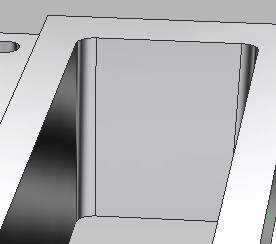

At a speed of more than 600 mt/min, against the 8 mt/min of a wire erosion, the wire “cleans itself”, eliminating the annoying barrel effect.

The walls can be parallel, or inclined, and with the same simplicity with which a rectangular quarry is carried out, quarries can be carried out with any profile.

The contours to be cut can be generated directly on the machine through the CAM part of the CNC, which is entered directly in DXF format.