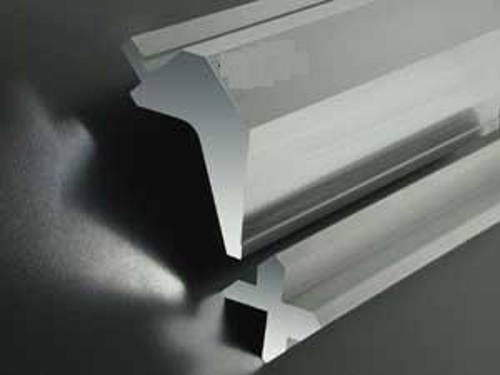

Carbide and diamond – Inserts, plates and profiles for woodworking

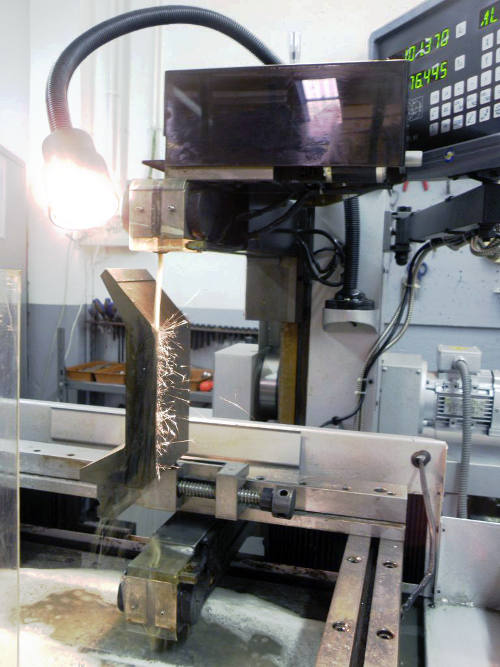

The execution of profiles on carbide or diamond inserts has been carried out for years with wire EDM machines, especially for quantities that do not justify the production of inserts already profiled by sintering.

In the furniture, windows and doors sector, and in general in the woodworking sector, the need to frequently change the models produced and to insert new ones requires tool manufacturers to be quick in meeting their requests, which are also increasingly limited in quantity.

The adoption of wire erosion has therefore been for many an obligatory choice, and often the purchase of a used machine has solved the problem.

But, in addition to saving money on purchase, compared to a new machine, a conventional erosion machine still has a cost of ownership, especially if old, considerable.

Among distilled water, filters, ion exchange resins, wear parts, and, most important of all, brass wire, it goes from 4 € / hour to 8 € / hour and beyond. So the daily cost ranges from 50 to 150 euros per day depending on the hours of work.

With E.cut the operating cost never exceeds 0,4€/hour!

The bill is therefore soon made. The daily cost, even in the case of continuous work of 24 hours, does not exceed 10 euros.

There are no tricks or mysteries. The simple fact of not throwing the wire, (see on the site the technical and functional features), allows you to slide it at 600 m / min instead of 6mt / min. No more need for distilled water, filters, resins, or other.

Paradoxically, if the competitor has E.cut, it has lower prices, earns more, and… you take the market!