Take the order!

Perfect and impeccable.

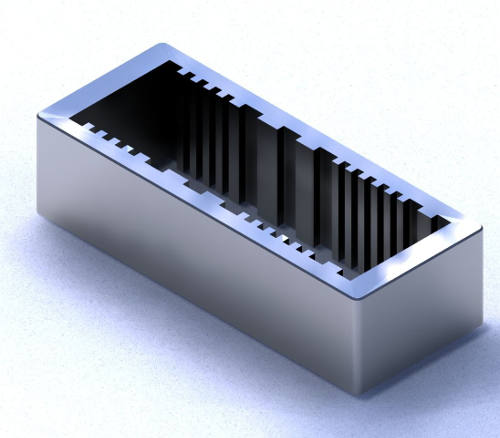

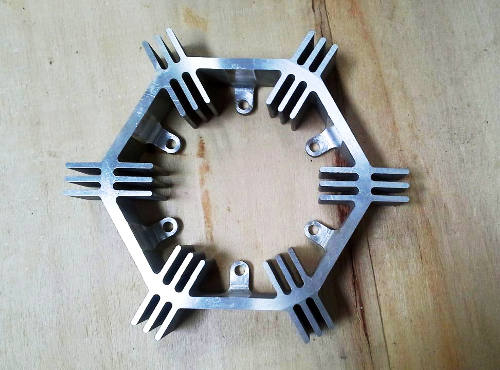

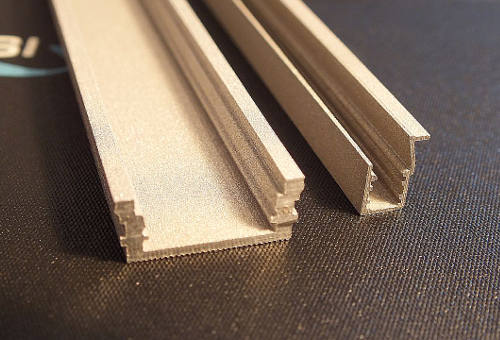

In front of a piece of this kind (about 60×40 mm x 4mm thickness) any good mechanic stops to reflect.

The first question you ask concerns the mind of those who designed it!

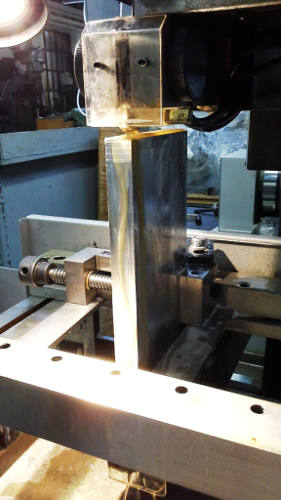

Once you have ascertained that this is the way to do it, you begin to think about how to do it. Work center, broach for the teeth of the hole, teeth of the half-corona,.. If then the material is difficult, or must be treated the matter becomes even more complicated.

In the end, only wire erosion remains. If you already have it, that’s fine, otherwise with traditional processes it’s a nice headache,

But with wire erosion, the cost is still high. The removal times are the same as they are, the placing times, with the need to respect guidelines and phases, too. If we put too many pieces one on top of the other to gain some time, there is the trap of the barrel effect, so the precision goes to be blessed …

If your competitor has an E.cut, he’ll almost certainly take the order!

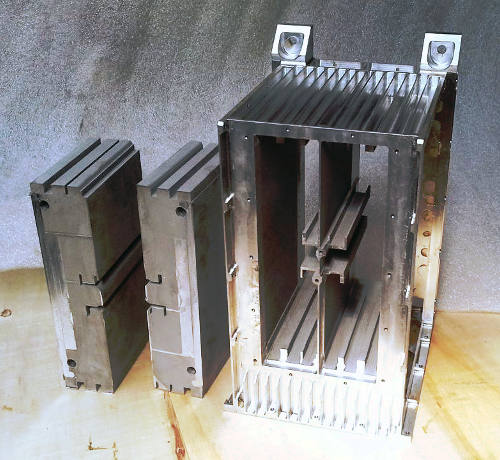

With E.cut you can easily “pack” about fifty pieces and cut them all in one go.

Since there is no beating effect, from the first to the last will be in the couple of hundredths of tolerance.

Add that the hourly cost of exercise is more than ten times lower, so even if you go over it again to bring the roughness up to 0.8 Ra, the final cost will still be extremely low.

I

I’ll cost you.

If you make your customer pay half of what it would cost him with a conventional wire, he’s very happy, and you still earn a lot of money!

Probably that’s why those who own an E.cut don’t care much about letting them know!