Difficult materials ? It’s not that easy!

Of course, the latest generation of tools have often helped to solve the problem of machining difficult materials such as stainless steel, titanium, inconel, monel, kidney’, ecy…,….

The machining of alloys whose characteristic is to harden at the high temperatures developed by the cut, is still to be addressed with great care, because the mistakes cost dear, very dear, given the high cost of the material.

Wear, breakage, and therefore the cost of tools often affects in an unexpected way. The risks, and the “rognosis” of the processing of these materials leads to estimates that take into account all this, and therefore to high final costs, and to the loss of orders that would be interesting.

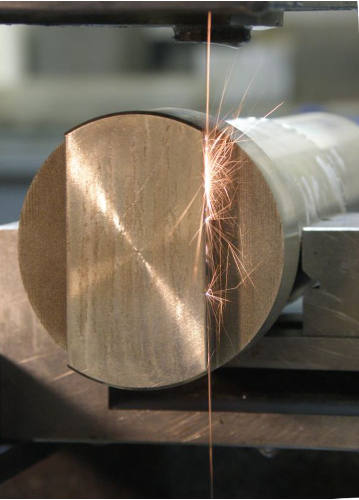

Wire erosion would be the ideal solution: no influence of the toughness and hardness of the material, absolute precision of machining, no broken or worn tools, no chips, but scrap resaleable at cost.

Unfortunately, the high hourly cost, (from 5 to 8 euros/hour of only operating cost!), makes it impractical to adopt it!

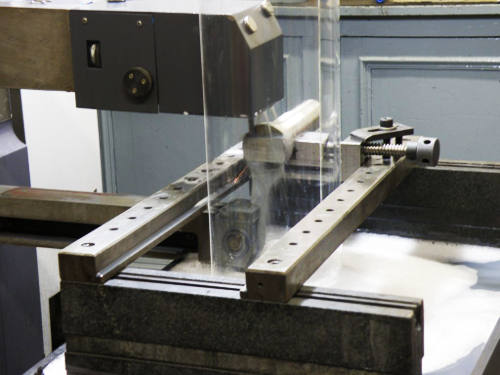

The working with E.cut represents in these cases a “magic” and revolutionary solution.

The hourly cost of less than 0.4 €/hour of E.cut is the basis of the “magic” that brings the cost of machining this piece to less than a tenth of the previous milling.

Precise, clean and burr-free. An impeccable solution.

The E.cut technology, with the possibility to cut thicknesses up to 300 mm already with the smallest machines, allows to revolutionize and to face in a totally new way the “process” to obtain certain pieces.