Few, complicated… and now.

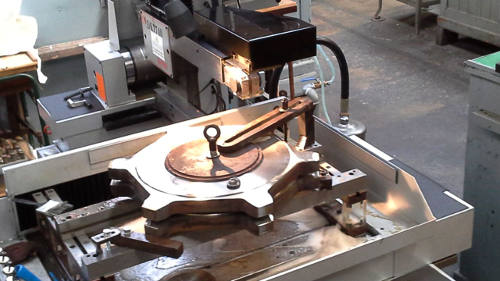

These two toothed crowns were becoming a problem! The module is not standard, and there’s no creator ready. As usual the customer needs it right away.

Of course, a CNC milling machine, and so on. But the thickness, and the particularly difficult material make the cost rise, to the point of making it almost prohibitive.

Wire EDM, therefore. But that who owns it is not there waiting for you,… and then a wire erosion has its price!

In many sectors there are not large numbers, and Ecut that between operating cost and depreciation cost does not exceed 3 € / hour is an unsurpassed solution.

If you are in competition with those who own an Ecut, you have no choice in such situations. He takes the order.

Forget the sterile clichés about Chinese living with a handful of rice. Look at the pictures next door. You’ll notice the dirt, which is what’s immediately obvious!

But there are only two people (two!!) who make 19 cars go, who work day and night. The cars, not the people. They do their 8 hours, like everywhere. Just think how much people here in Italy cost you!

Returning to the two crowns from which we started, the client arrived in the afternoon at 4 p.m., and at 9 p.m. his crowns were finished! The next morning he took them away!

Two hours and thirty minutes for the sixteen teeth with a diameter of 200 mm, with perfect geometry, cut without any burrs, and without superficial hardening!

If they had been ten pieces, even better! The smallest Ecut cuts up to a thickness of 300 mm. Then put one on top of the other, just one placement and for 30 hours the machine would have worked… alone.

The total cost is about 7,5 euro… but the customer was very happy to pay 50!