Ecut and… turning

At first glance it would seem that in a lathe, especially in an automatic lathe, there are few or no reasons to have an Ecut, a wire erosion. We thought so too, until Mr. Cottarelli made us change our mind, buying one.

With over 60 automatic lathes, sliding headstock lathes, multispindle lathes, numerical control lathes, with machines over 40 years old, and very modern machines, the CTA of Gordona (Sondrio), well represents the hundreds of companies of this type scattered in Italy.

“No, we do bar turning, we’re not mold makers. We don’t need wire erosion. That’s the standard reaction.

Mr. Cottarelli instead wanted to see Ecut at work, and asked himself what he could do with it!

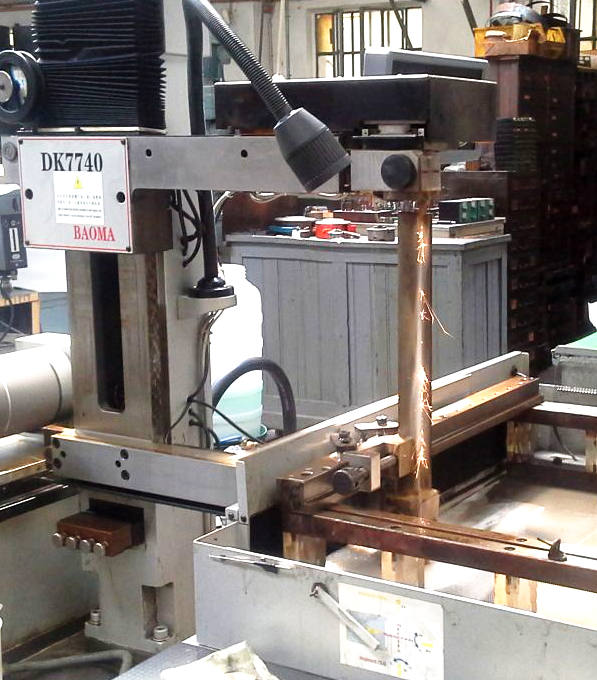

With a disenchanted eye and free from conventions he considered this wire that in 2 tenths cuts any metallic material of any hardness. And verified the cost of the machine and operating cost, he decided to buy it.

Today he has relegated to the attic some sophisticated sharpening machines with which he built and resharpened tools. The advantage, especially for profiled tools, is incalculable.

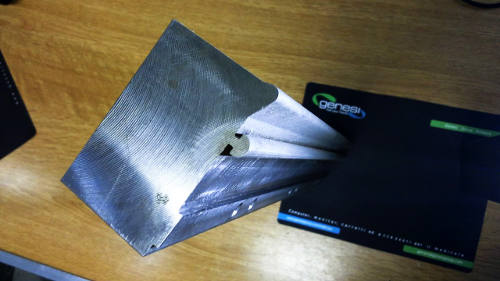

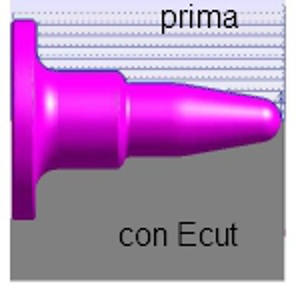

With Ecut, directly from the DXF profile of the workpiece he gets the tool. Perfectly stripped in all walls, not just on the front. Ready to go into the machine… with 0.1 radii, unthinkable with grinding wheels.

No more grinding wheels, profile projectors, Diaforms and the like. No more dust, no more people spending hours sharpening… and burnt fingers.

One of the highest costs in the company has been drastically reduced!

The ease in generating profiled tools at a negligible cost allows the use of old and abundantly depreciated machines for machining operations performed by sophisticated numerical control machines.

These chess machines, for example, are produced with a normal parallel lathe with profiled tools, at practically no cost!

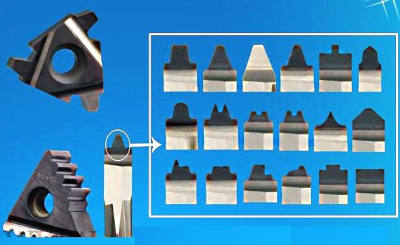

The contraction in quantities today often makes the cost of tools disproportionate. Threads with special steps involve the purchase of “boxes” of 10 inserts at a cost of hundreds of euros. Often these inserts are no longer used … and remain in stock!

With Ecut the tool can be quickly obtained from a simple brazed, or from a standard insert, at a negligible cost, in the quantity strictly necessary, and… resharpened in an instant.