Dollars… not words.

The analysis that precedes the adoption of a new technology takes into account many factors: precision of the new process, reliability of the plant, reliability of the manufacturer/supplier, guarantee of durability, guarantee of assistance, etc..

But in the end the predominant factor is the economic advantage compared to the conventional methods in use.

The examples below always involve a great economic advantage, and often represent a completely new way of making a piece.

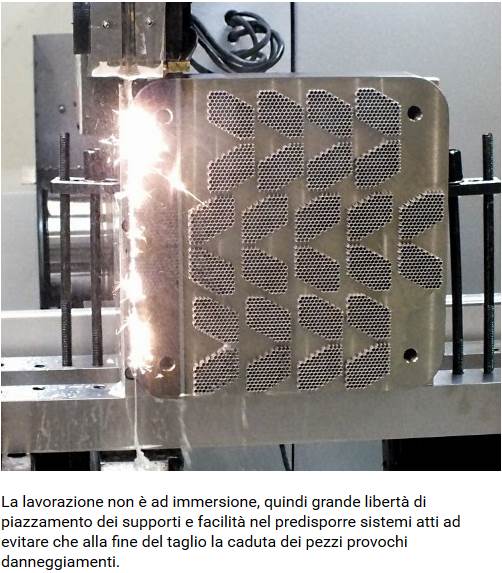

These teeth on the tip of delicate stainless steel biopsy needles must be absolutely burr-free.2 and 3 mm diameter and a few tenths of a tube thickness make it difficult to work with any other system, so extremely expensive. With Ecut it is possible to overlap up to 50 needles and make the cut in a single stroke, obtaining a ridiculous cost per piece.

With a conventional wire erosion, the intermittent cut deflects the washing, which is under pressure, with the consequence of the wire breakage.

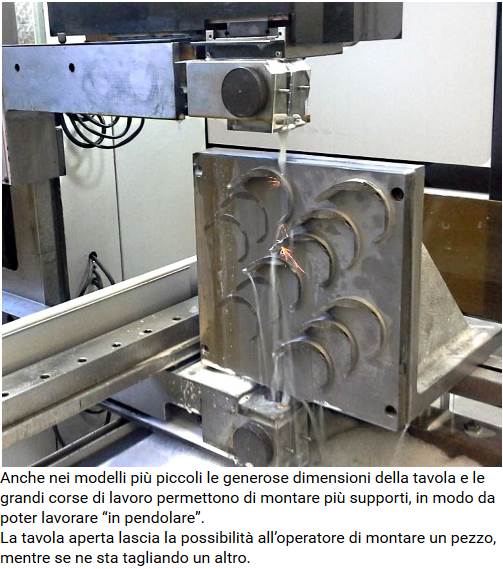

No problem with Ecut. The washing is by gravity, the work is not by immersion, and the loading and unloading of the pieces from the mask is easy.

These three 30 mm thick 718 lnconel plates are cut into three at a time, (90 mm ). The size of 1300 mm by 380 mm far exceeds the dimensions of the table, but not being immersion can be worked without problems. Cost of cutting approx. 4€. NO system costs so little!

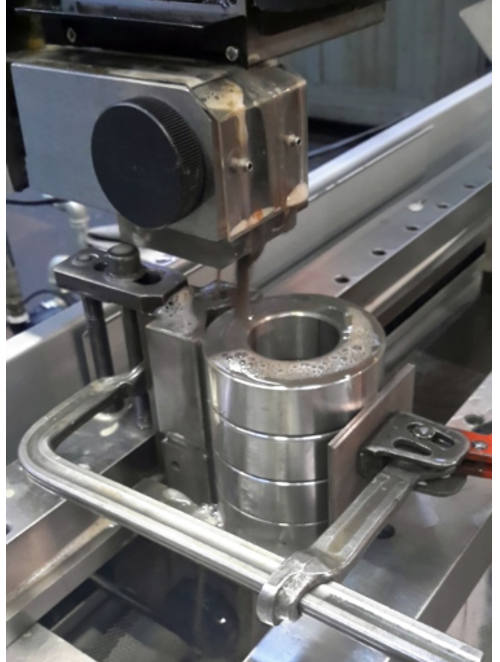

Two opposite keys must be made on these rings. The cost with Ecut is a couple of euros. But very important is that it was not necessary any locking tool, only a simple prism and a clamp, the angular accuracy is absolute, and, much more important, the 32 rings were ready immediately, without waiting for the availability of third parties.

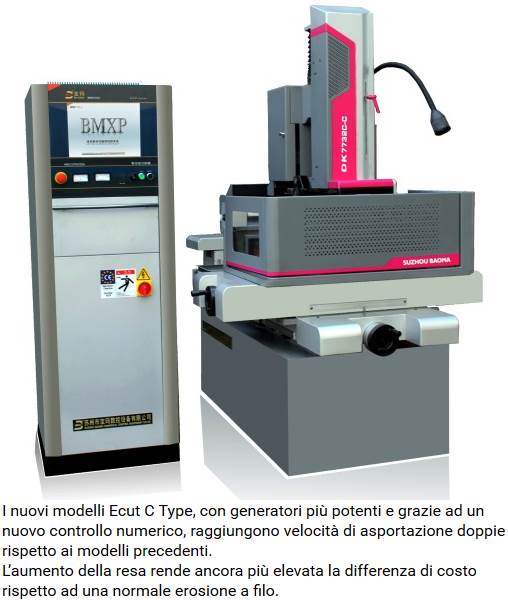

With less than 40,000 euros you can have an Ecut with strokes of 400x320x500 cutting height!