Remove or cut?

For these simple processes the use of Ecut has drastically reduced the costs of realization.

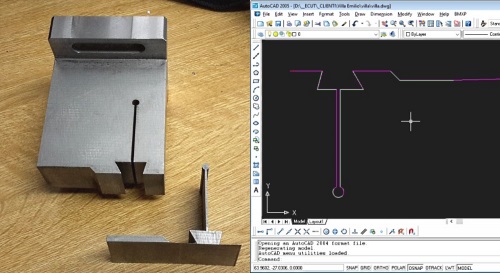

The execution of this cradle on a series of only three stainless steel pieces requires at least two placements. The deep and thin cut presents risks of breakage of the cutter, the culisse has two different inclinations, therefore two different cutters. Cutters for conical slots on this material break easily…

The execution through Ecut takes place in a single nesting, the tool is the only wire, and the work program is obtained quickly with the CAD on board the machine:

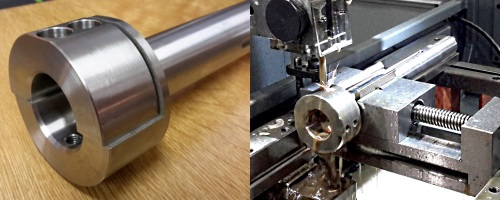

This series of 16 Inconel pieces could be obtained by cutting the moving part with a circular saw, or with a band saw. However, the material is particularly difficult, and tool breakage is very frequent. The required precision is also quite tight.

With Ecut, a simple, little vice is enough to hold the piece. The lack of an immersion tank allows the workpieces to be processed with a long shank. The accuracy is within 0.015 mm, and the cut of only 0.2 mm. are the ideal solution from the technological point of view, and sensational from the economic point of view.

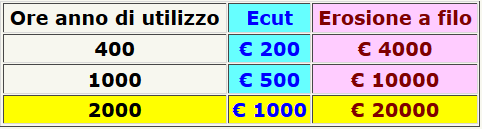

The same machining operations performed with Ecut could be performed with conventional wire erosion, but too often the difference in hourly operating cost, (over 20 times greater, 0.5 euros/hour Ecut against 15 euros/hour normal wire erosion), make this solution economically unthinkable.

With Ecut no tools, no heavy clamping, no swarf, no dirt,… and, almost always, no people!