You need it too

All you need is an Ecut to find out how many jobs it can be useful in the workshop. One year after the purchase of an Ecut, two more have been purchased. “It has become the most clogged machine”, we were told. Purchased to profile carbide plates, “Since we made a key, no one wants to use the stockpile anymore! Even at great heights, perfect keys, to the nearest cent, with no one following the machine. You attack and leave, great!”.

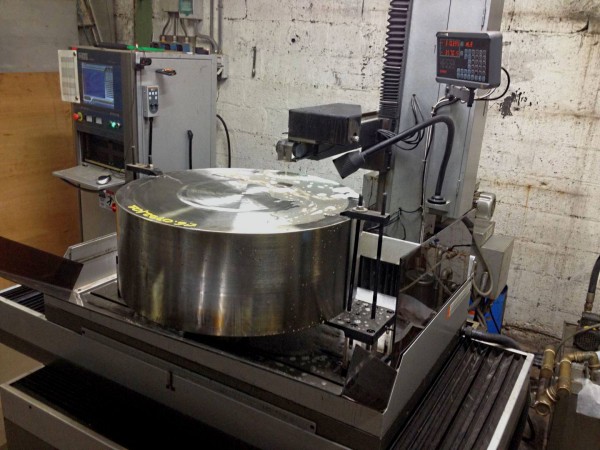

In the following image, from a round of 900mm diameter, 350mm thick, almost a ton of weight, a complex internal profile of about 400mm diameter is obtained. No chips, but a nice block of precious steel to be used for other pieces.

On the contrary, these small objects in stainless steel, brass and silver are obtained with the same machine!

Of course, if only these processes were carried out, a smaller machine would be less cumbersome, but the precision and finish required are the same for a small or large machine.

On the contrary, these small objects in stainless steel, brass and silver are obtained with the same machine!

Of course, if only these processes were carried out, a smaller machine would be less cumbersome, but the precision and finish required are the same for a small or large machine.

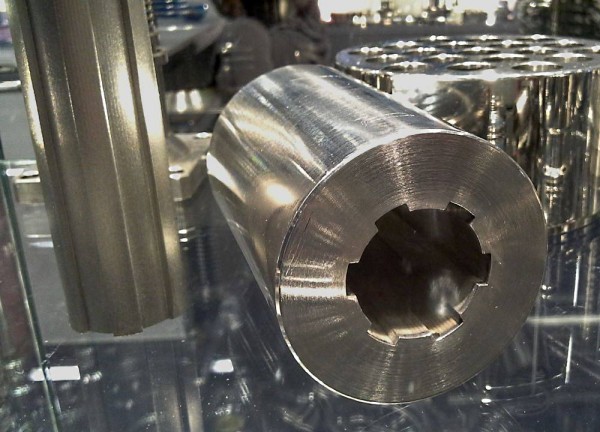

Titanium and stainless steel tubes. Profiled cut. The full cutting height of the machine, 500 mm, is normally used. Machining also in commuter mode, so it is possible to unload and load the pieces while the machine is cutting the other column. The lack of an immersion tank allows placements and masks unthinkable with conventional EDM machines.

.